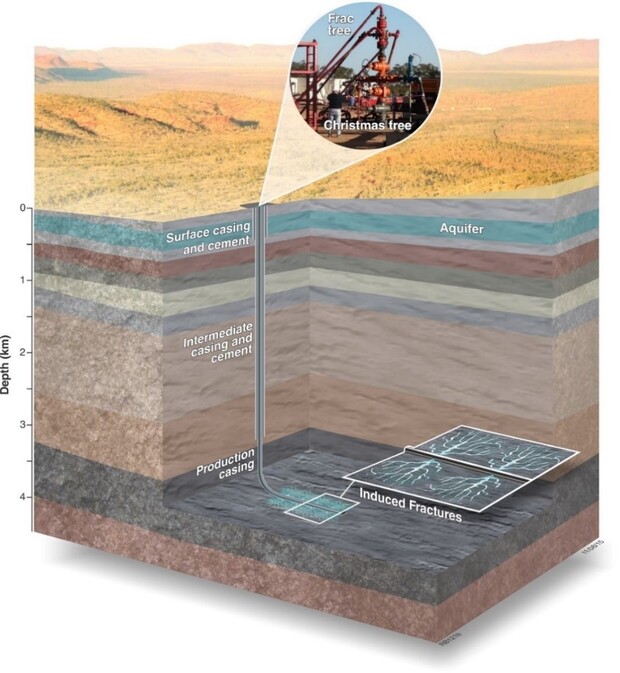

Hydraulic fracture stimulation, also referred to as hydraulic fracturing or fracking/fraccing, is the underground petroleum extraction process that involves the injection of fluids under high pressure into low permeability rock to induce fractures to increase the rock’s permeability. This term is as defined in the Petroleum and Geothermal Energy Resources (Hydraulic Fracturing) Regulations 2017.

In Western Australia, shale and tight sandstones that are prospective for natural gas are typically found between 2,000 to 5,000 metres underground.

How does hydraulic fracturing work?

During hydraulic fracturing, a specially-designed fracture fluid is pumped at pressure down a petroleum well lined with steel casing. In preparation for hydraulic fracturing, the steel casing has been perforated at specific intervals/depths to create a channel into the targeted rock formation. These perforations allow the fluid to come into contact with the rock formation, which at pressure creates a network of small fractures in the rock.

The fracture fluid is typically composed of 90 per cent water, 9.5 per cent proppant (usually sand) and 0.5 per cent chemical additives added to the mixture. The proppants suspended in the fluid remain in the fractures and hold them open after the pumping has stopped. This provides a pathway for the gas to flow into the well and be recovered.

These fracture pathways are typically three to six millimetres wide, but can extend 400 metres horizontally and up to 100 metres vertically within the gas-bearing rock formation.

Each well to be hydraulically fractured is carefully designed, based on scientific models of the rock’s properties, and the process is closely monitored in real time because of the high pressures involved (690 bar or 10,000psi).

Water use

The water used in a fracture fluid may be fresh, saline, bore or recycled. Up to 80 percent of the fluid used during a hydraulic fracture stimulation can be recovered. If not reused in another well, the fluid can be stored safely and the water allowed to naturally evaporate, leaving behind a small residue. This residue is tested and, if required, removed safely and disposed of at a licensed waste facility.

Chemical use

The chemical additives in the fluid serve the following purposes:

- to make the fluid thicker and suspend the sand in the fluid;

- to allow the fluid to flow more easily into the fractures;

- to prevent corrosion damage to the well;

- to stop bacteria build up; and

- to leave the sand proppant in the newly-created fractures.

All hydraulic fracturing fluids, including their chemical composition, are assessed by the operator and by government agencies. The details of these chemicals must be publicly disclosed in full and they are listed on the Department of Mines, Industry Regulation and Safety (DMIRS) website.

When can hydraulic fracturing occur and how long does it take?

Hydraulic fracturing can occur during three stages of the petroleum development cycle – exploration, evaluation and production. Generally, the process is undertaken only once for the life of a well.

During exploration, fracturing of a vertical well may occur to test different rock formations for gas. Hydraulic fracturing of unconventional reservoirs has only been undertaken at the exploration stage in Western Australia.

During evaluation, multiple vertical and/or horizontal wells may be drilled and fractured to determine the physical extent of a newly discovered gas field.

During production, vertical or horizontal wells are drilled and can undergo hydraulic fracturing to enhance commercial flows of hydrocarbons.

The hydraulic fracturing process can take between one to 10 days.

Hydraulic fracturing equipment at the Arrowsmith 2 well site in the northern Perth Basin in 2012

What does a shale or tight gas well site look like?

A shale or tight gas well site typically requires 1.5 to 2 hectares of land to be cleared for site access. A well pad is generally drilled in the centre of the clearing, using a drill rig. Other equipment such as data monitoring vans, vehicles, sand and chemical storage units, pumping trucks and collection ponds are also located on the site.

The number of well sites required when developing a shale or tight gas field depends on the size of the gas field being targeted. Advances in horizontal drilling techniques now enable several wells to be drilled from one location. These wells extend to a maximum depth of five kilometres, deviating horizontally for one to two kilometres once reaching the gas-bearing rock.

This significantly limits the footprint of surface activity, including the number of access tracks. For example, if a petroleum company drilled six shale gas wells from one well pad and used horizontal drilling, it is estimated one well pad would be required for every 225 hectares (2.25km²) of land within a discovered gas field. Well pads would be approximately 1.5km apart from each other.

What happens after hydraulic fracturing is completed?

After hydraulic fracturing is completed, most equipment is moved offsite. This reduces the site footprint from around 1.5-2 hectares down to 0.4-1.2 hectares. Generally, all that remains visible at the surface is a series of sealed valves (Christmas trees) about two metres high. Once the site reaches the production stage, it will also include a gas pipeline (pipelines are buried or isolated within a security fenced area) which leads to a gas processing plant.

Gas can flow from a production well into pipelines for 10 to 40 years. The gas stops flowing when the pressure reduces over time. Eventually, the pressure of the earth will crush the sand and the fractures in the rocks will close up.

At the end of a well’s production life, the well is sealed with multiple cement plugs, decommissioned and the site is rehabilitated.

Is hydraulic fracturing a new process?

No. Hydraulic fracturing has been a commercial process in the international oil and gas industry since 1947.

Historically, hydraulic fracturing involved pumping a small amount of fluid under relatively low pressure into a targeted conventional rock formation to open up small gaps in the rock to increase oil and gas flow. Shales were not viewed at the time as potential gas resources. Recent developments in technology mean hydraulic fracturing can now be used to create small fractures to release gas from shales and other tight rocks.

More than 2.5 million hydraulic fractures have been completed worldwide, with about one million of those for shale gas and tight gas and/or oil.

In Western Australia, hydraulic fracturing has been used in wells drilled in both conventional and unconventional reservoirs since 1958. About 780 hydraulic fracturing activities have been conducted in Western Australia. Most of these were low pressure, low volume hydraulic fracturing activities on conventional oil and gas wells on Barrow Island to enhance oil recovery in producing wells. Between 2005 and 2015, 11 exploration wells have undergone high pressure hydraulic fracturing in Western Australia.

Terms used

casing: large-diameter steel pipe that is cemented into a wellbore to prevent the rocks from caving in and stops unwanted fluids from entering the hole from the surrounding rocks.

natural gas: naturally occurring mixture of hydrocarbon gases that is highly compressible and expansible. Methane [CH4] is the chief constituent of most natural gas (constituting as much as 85 per cent of some natural gases), with lesser amounts of ethane [C2H6], propane [C3H8], butane [C4H10] and pentane [C5H12]. Impurities can also be present in large proportions, including carbon dioxide, helium, nitrogen and hydrogen sulphide. Natural gas produced from shale reservoirs is known as shale gas.

perforate: the creation of small holes in the casing into the adjacent producing formation.

perforation: the pathway created through the casing into the reservoir formation, through which fluids pass.

permeability: the ability, or measurement, of a rock’s ability to transmit fluids.

petroleum: a complex mixture of naturally occurring hydrocarbon compounds found in rock in liquid, gaseous or solid form (i.e. crude oil, natural gas, or bitumen).

prospective: likely to contain natural gas resources.

proppant: small particles, usually sand, mixed with fracturing fluid to hold fractures open after a hydraulic fracturing treatment.

reservoir: a subsurface body of rock having sufficient porosity and permeability to store and transmit fluids. Sedimentary rocks are the most common reservoir rocks.

shale: a sedimentary rock composed of clay-sized particles that is laminated or layered.

tight sandstone: a sedimentary rock composed mainly of sand-sized minerals or rock grains that has very low permeability and porosity.

well pad is the area that has been cleared for a drilling rig to work on a plot of land designated for natural gas or oil extraction. A standard single well pad for conventional oil or gas typically affects a surface area measuring 100 metres by 100 metres. When multiple wells are drilled from a well pad, the surface area of the site will be larger, in some cases double the size (100 metres by 200 metres).